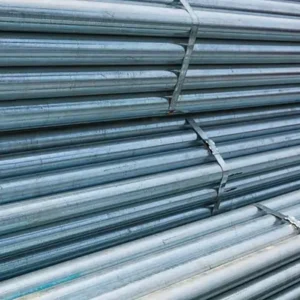

What is Galvanized Steel and Painted Steel?

The construction and manufacturing sectors as well as industrial applications widely employ galvanized steel and painted steel materials. The coating materials protect against corrosion yet function differently as protective measures between these steel products.

Steel that receives a zinc coating obtains protection from oxidation and rust through the zinc barrier. Carbon or alloy steel makes up the steel core which receives a zinc protection through its formation of zinc oxide and zinc hydroxide protective layers.

Painted steel contains carbon or alloy steel that receives color paint as protective coating. The steel product receives improved aesthetic qualities and corrosion protection from this applied paint layer.

Differences Between Galvanized and Painted Steel

Although both types of steel have the same base material, the primary difference lies in their coating layers.

| Feature | Galvanized Steel | Painted Steel |

|---|---|---|

| Coating Material | Zinc | Epoxy, PU, or PVDF paint |

| Corrosion Resistance | High (zinc layer protects from rust) | Moderate (paint protects but wears off over time) |

| Durability | Lasts 50+ years | Requires repainting every 5–7 years |

| Scratch Resistance | Strong | Weaker; scratches expose steel to corrosion |

| Aesthetic Appeal | Limited (gray/silver) | Wide range of colors |

| Cost | More cost-effective for long-term use | Higher maintenance cost over time |

Methods for Coating Galvanized and Painted Steel

The coating process for each type of steel differs significantly.

Galvanization Process

- Hot-Dip Galvanizing – The steel is dipped into a bath of molten zinc at around 450°C, ensuring strong adhesion and long-lasting protection.

- Electrogalvanization – A zinc coating is applied to the steel surface using electric current, forming a thinner but smooth protective layer.

Hot-dip galvanizing is the most widely used method for zinc-coated steel.

Painting Process

- Powder Coating – Epoxy paint is electrostatically sprayed onto the steel surface, ensuring strong adhesion.

- Thermal Coating – A heated paint layer is applied through spray guns, rolling, or hot-dipping, providing enhanced protection and color.

A spray gun is commonly used to apply epoxy paint on steel surfaces.

Comparing Galvanized and Painted Steel Performance

Both galvanized and painted steel offer strong structural integrity, but they differ in coating thickness, scratch resistance, durability, and cost.

1. Coating Thickness

- Galvanized steel typically has a zinc layer of 0.3–2.5 mm, which provides excellent corrosion resistance.

- Painted steel consists of three layers:

- Primer – Ensures strong adhesion to steel.

- Undercoat – Enhances corrosion protection.

- Finish Coat – Adds color, UV resistance, and fire resistance.

Applying paint requires compatibility among multiple layers, whereas galvanization focuses on coating uniformity and thickness.

2. Durability and Scratch Resistance

- Galvanized steel offers superior corrosion resistance, particularly in coastal or harsh weather conditions. The zinc layer protects against rust by forming a zinc oxide barrier.

- Painted steel provides some scratch resistance, but if the surface is damaged, rust can spread quickly. Touch-up paint can fix minor scratches, while galvanization cannot be easily repaired once scratched.

Galvanized steel has stronger scratch resistance compared to painted steel.

3. Cost Comparison

- Galvanized steel is more affordable over the long term because it requires less maintenance.

- Painted steel has higher initial costs due to the additional painting process and requires periodic repainting every 5–7 years.

For large-scale projects, galvanized steel helps reduce maintenance expenses, while painted steel is ideal for custom aesthetics.

4. Custom Color Options

- Painted steel allows a wide variety of colors, making it perfect for architectural and decorative applications.

- Galvanized steel retains its natural gray/silver finish, which is suitable for industrial and structural uses.

Painted steel offers more color options for customers.

Which Steel is Better for Your Project?

Choose Galvanized Steel If:

✅ Your project is in a harsh, coastal, or high-humidity environment.

✅ You need a low-maintenance, long-lasting material.

✅ You want high corrosion resistance with minimal repainting.

Choose Painted Steel If:

✅ You need custom colors for aesthetic appeal.

✅ Your project requires UV-resistant, fire-resistant, or decorative coatings.

✅ You are willing to repaint periodically for maintenance.

Midwest Steel: Your Trusted Supplier for Galvanized and Painted Steel

Midwest Steel is a leading U.S. supplier of galvanized and painted steel for construction, manufacturing, and industrial applications.

Why Choose Midwest Steel?

✅ High-Quality Products – Midwest Steel provides top-grade galvanized and pre-painted steel sheets, coils, and pipes.

✅ Custom Processing – Offers cut-to-size services, color coatings, and custom fabrication.

✅ Competitive Pricing – Affordable rates for bulk and wholesale orders.

✅ Nationwide Delivery – Fast shipping across the United States for large-scale and small-scale projects.

Conclusion

The protective layers on galvanized steel differ from painted steel in terms of durability and maintenance needs as well as price point.

The selection of galvanized steel works perfectly for industrial purposes and outdoor use when seeking extended durability with protection against corrosion.

Aesthetic-focused projects requiring decorative finishes together with customizable color treatments should use painted steel.

Get high-quality custom galvanized and painted steel products from Midwest Steel which offers both competitive pricing along with quick delivery. Midwest Steel offers customized prices to clients who reach out through phone contact