Manufacturing Welded Steel Pipe: Process, Types, and Applications

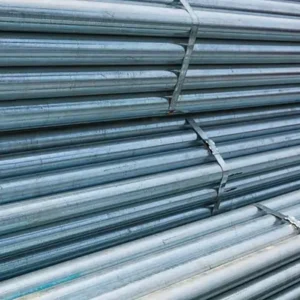

Welded steel pipes are essential components in various industries, including construction, automotive, oil and gas, and water transportation. They are manufactured by forming steel plates or strips into cylindrical shapes and joining them through welding. This process ensures durability, strength, and cost-effectiveness, making welded steel pipes a preferred choice for many applications. This article explores the manufacturing process, different types of welded steel pipes, and their applications.

Manufacturing Process of Welded Steel Pipes

The production of welded steel pipes follows a systematic process to ensure high quality and efficiency. The key steps include:

1. Material Selection and Preparation

The process begins with selecting high-quality steel plates or coils, typically made from carbon steel, stainless steel, or alloy steel. These materials are inspected for defects before processing.

2. Forming the Pipe

The steel strip or plate is then passed through rollers to shape it into a cylindrical form. Depending on the type of pipe being manufactured, this forming process may vary:

- Electric Resistance Welding (ERW): Steel strips are continuously rolled and welded along the seam.

- Spiral Submerged Arc Welding (SSAW): The steel coil is formed into a spiral shape and welded.

- Longitudinal Submerged Arc Welding (LSAW): Large steel plates are formed and welded along the longitudinal seam.

3. Welding

The formed steel is welded using different techniques, such as:

- Electric Resistance Welding (ERW): Uses high-frequency electrical current to heat and join the steel edges.

- Submerged Arc Welding (SAW): Utilizes a continuously fed electrode and a blanket of granular flux to protect the weld from impurities.

- Gas Metal Arc Welding (GMAW): Uses a shielding gas to prevent oxidation.

4. Heat Treatment and Annealing

To relieve stress and improve mechanical properties, the welded pipes undergo heat treatment. This process enhances their strength, ductility, and corrosion resistance.

5. Sizing and Cutting

The welded pipes are then passed through sizing rollers to ensure uniform diameter and thickness. They are cut into required lengths using high-precision cutting machines.

6. Inspection and Quality Control

To meet industry standards, welded steel pipes undergo rigorous inspections, including:

- Ultrasonic Testing (UT): Detects internal defects.

- Radiographic Testing (RT): Examines weld integrity.

- Hydrostatic Testing: Ensures pressure resistance.

- Dimensional Inspection: Verifies thickness, diameter, and length.

Types of Welded Steel Pipes

There are several types of welded steel pipes, each suited for specific applications:

1. ERW (Electric Resistance Welded) Pipes

- Commonly used in oil and gas transportation, structural applications, and water pipelines.

- Known for its smooth surface finish and high dimensional accuracy.

2. SSAW (Spiral Submerged Arc Welded) Pipes

- Used in large-diameter pipelines for water, gas, and structural applications.

- Offers flexibility in diameter and wall thickness.

3. LSAW (Longitudinal Submerged Arc Welded) Pipes

- Ideal for high-pressure applications such as oil and gas pipelines.

- Provides superior strength and toughness.

Applications of Welded Steel Pipes

Welded steel pipes play a crucial role in various industries:

- Construction: Used for structural frameworks, scaffolding, and underground drainage systems.

- Oil & Gas: Used in pipelines for transporting crude oil, natural gas, and refined products.

- Water Supply & Sewage: Essential for potable water distribution and sewage treatment plants.

- Automotive Industry: Used in exhaust systems, roll cages, and chassis components.

- Mechanical Engineering: Applied in the manufacturing of boilers, heat exchangers, and industrial machinery.

Conclusion

Welded steel pipes are indispensable in modern industries due to their strength, cost-effectiveness, and versatility. Understanding the manufacturing process, different welding techniques, and their applications helps industries choose the right type of welded steel pipe for their needs. As technology advances, the production of welded steel pipes continues to improve, ensuring higher efficiency and quality for industrial and commercial applications.

Click here to Contact us now.