Hot Rolled Steel Rectangular Tubing at Midwest Steel Supply: A Comprehensive Overview

Introduction

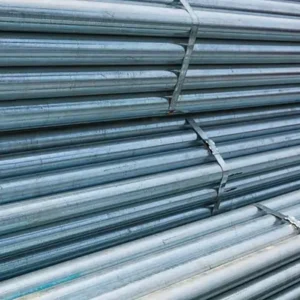

Hot-rolled steel rectangular tubing is a versatile and widely used material in various hot-rolled, from construction to manufacturing. Known for its strength, durability, and cost-effectiveness, it is essential in many structural applications. At Midwest Steel Supply, customers can find a comprehensive selection of hot-rolled steel rectangular tubing tailored to meet diverse project needs. This article will explore the characteristics, benefits, applications, and purchasing considerations for hot-rolled steel rectangular tubing at Midwest Steel Supply.

What is Hot Rolled Steel Rectangular Tubing?

Definition

Hot rolled steel rectangular tubing is a type of steel tubing that is formed by rolling steel at high temperatures. This process allows the steel to be shaped into rectangular sections, which are then cooled and cut to specific lengths. Hot rolling involves heating the steel above its recrystallization temperature, making it easier to shape and form.

Manufacturing Process

The manufacturing process of hot rolled steel rectangular tubing involves several key steps:

- Heating: Steel billets are heated to high temperatures in a furnace, making them malleable.

- Rolling: The heated steel is passed through rollers that shape it into the desired rectangular profile.

- Cooling: After rolling, the tubing is cooled, allowing it to solidify in its new shape.

- Cutting: The cooled tubing is cut to specified lengths based on customer requirements.

- Finishing: The final product may undergo additional processes, such as surface treatment or coating, to enhance its properties.

Characteristics of Hot Rolled Steel Rectangular Tubing

1. Strength and Durability

Hot-rolled steel rectangular tubing is known for its high strength-to-weight ratio, making it suitable for demanding applications. The hot rolling process enhances the material’s structural integrity, allowing it to withstand heavy loads and resist deformation.

2. Versatility

The rectangular shape of the tubing provides versatility in design and construction. It can be easily welded, cut, and fabricated, making it ideal for various applications, including frames, supports, and structural components.

3. Cost-Effectiveness

Hot rolled steel rectangular tubing is often more affordable than other types of steelHot-rolleduch as cold-rolled or stainless steel. This cost-effectiveness makes it a popular choice for budget-conscious projects without compromising quality.

4. Surface Finish

The surface of hot rolled steel rectangular tubing typically has a rough finish due to the manufacturing process. While this may not be aesthetically pleasing for all applications, it can be advantageous for certain industrial uses where a rough surface promotes better adhesion for coatings and paints.

Benefits of Using Hot Rolled Steel Rectangular Tubing

1. Structural Integrity

The high strength and durability of hot rolled steel rectangular tubing make it an excellent choice for structural applications. It can support significant loads and is commonly used in construction, manufacturing, and engineering projects.

2. Ease of Fabrication

Hot rolled steel rectangular tubing can be easily fabricated to meet specific projects Hot-rolledts. It can be cut, welded, and shaped with relative ease, allowing for flexibility in design and construction.

3. Availability

Midwest Steel Supply offers a wide range of sizes and specifications for hot rolled steel rectangular tubing. This availability ensures that customers can find the right tubing for their specific needs without extensive lead times.

4. Resistance to Corrosion

While hot rolled steel is not inherently corrosion-resistant, it can be treated with a coating hot-rarolleddd that enhances renhancessce to environmental factors. This treatment can extend the lifespan of the tubing and reduce maintenance costs.

Applications of Hot Rolled Steel Rectangular Tubing

1. ConstructionHot-rolled hot-rolled

Hot rolled steel rectangular tubing is widely used in construction for structural support-rolled and bracing. Its strength and durability make it ideal for buildings, bridges, and other infrastructure projects.

2. Manufacturing

In manufacturing, hot rolled steel rectangular tubing is used for machinery frames, equipment supports, and conveyor systems. Its versatility allows manufacturers to create custom solutions tailored to their specific production needs.

3. Automotive

The automotive industry utilizes hot rolled steel rectangular tubing for various applications, including chassis components and structural reinforcements. Its ability to withstand heavy loads and impacts makes it a reliable choice for automotive manufacturing.

4. Furniture

Hot rolled steel rectangular tubing is increasingly used in furniture design, particularly hot-rolled industrial-style pieces. Its aesthetic appeal, combined with strength, makes it suitable for tables, chairs, and shelving units.

5. Agricultural Equipment

In agriculture, hot rolled steel rectangular tubing is used for constructing equipment frames, trailers, and storage solutions. Its durability and resistance to wear make it ideal for demanding agricultural environments.

Purchasing Hot Rolled Steel Rectangular Tubing at Midwest Steel Supply

1. Product Selection

Midwest Steel Supply offers an extensive selection of hot rolled steel rectangular tubing in various sizes and thicknesses. Customers can choose from standard dimensions or request custom lengths and specifications to meet their project requirements.

2. Quality Assurance

When purchasing hot rolled steel rectangular tubing, it is essential to ensure that the product meets industry standards for quality and performance. Midwest Steel Supply maintains strict quality control measures to guarantee that all products meet or exceed customer expectations.

3. Competitive Pricing

Midwest Steel Supply is committed to providing competitive pricing for hot rolled steel rectangular tubing. By sourcing materials directly from manufacturers and maintaining efficient operations, the company can offer affordable options for customers.

4. Expert Guidance

For customers unsure about their specific needs, Midwest Steel Supply offers expert guidance to help determine the right type and size of tubing for their projects. Their knowledgeable staff can assist with product selection, specifications, and any technical questions.

5. Delivery and Logistics

Midwest Steel Supply provides reliable delivery options to ensure that customers receive their orders promptly. With efficient logistics and shipping practices, customers can expect timely delivery of their hot rolled steel rectangular tubing.

Conclusion

Hot rolled steel rectangular tubing is a vital material in various industries, offering hot-rolled, versatility, and cost-effectiveness. At Midwest Steel Supply, customers can find a comprehensive selection of hot rolled steel rectangular tubing tailored to meet diverse project needs. With its extensive product range, competitive pricing, and expert guidance, Midwest Steel Supply is a trusted source for high-quality hot rolled steel rectangular tubing.

Whether you are involved in construction, manufacturing, automotive, or furniture design, hot rolled steel rectangular tubing can provide the structural integrity and durability required for your projects. By understanding the characteristics, benefits, and applications of this material, you can make informed decisions and choose the right products for your specific needs. With Midwest Steel Supply as your partner, you can confidently tackle any project with the right hot rolled steel rectangular tubing.