Galvanized and Black Wire: A Complete Guide

In the world of construction, manufacturing, and agriculture, wire products play a critical role in shaping infrastructure and enabling a variety of operations. Among the most widely used wire types are galvanized wire and black wire. Each has its own properties, advantages, and ideal use cases. Understanding the difference between galvanized and black wire helps in choosing the right material for your needs—whether it’s for fencing, reinforcement, binding, or industrial manufacturing.

What is Galvanized Wire?

Galvanized wire is steel wire that has been coated with a layer of zinc to prevent rust and corrosion. This process is called galvanization, and it typically involves either:

-

Hot-dip galvanizing – where the wire is dipped into molten zinc

-

Electro-galvanizing – where zinc is applied using an electric current

The zinc coating acts as a protective barrier between the steel and the environment, especially in areas where moisture or humidity is present.

Benefits of Galvanized Wire

-

Corrosion Resistance: The zinc coating prevents rust even in wet or humid conditions, making galvanized wire suitable for outdoor and marine environments.

-

Durability: It has a long service life due to its high resistance to weather and chemicals.

-

Versatility: Used in fencing, construction, automotive parts, and even in household applications.

-

Low Maintenance: Galvanized wire typically doesn’t need repainting or coating, reducing upkeep costs over time.

-

High Tensile Strength: It can bear heavy loads and tension, making it reliable for structural applications.

What is Black Wire?

Black wire, also known as annealed wire, is untreated low-carbon steel wire. It has a smooth black surface, produced by annealing—a heat treatment process that softens the metal, increases its ductility, and improves its flexibility. Unlike galvanized wire, black wire does not have any zinc coating, which makes it more vulnerable to corrosion when exposed to moisture.

Benefits of Black Wire

-

Flexible and Malleable: Ideal for applications requiring bending, twisting, or tying without snapping.

-

Cost-Effective: Typically cheaper than galvanized wire due to fewer processing steps.

-

Perfect for Indoor Use: Frequently used in manufacturing, packaging, and binding inside warehouses or production facilities.

-

Ideal for Temporary Applications: Since it’s inexpensive and easy to manipulate, black wire is great for short-term or indoor use where rusting isn’t a concern.

Key Differences Between Galvanized and Black Wire

| Feature | Galvanized Wire | Black Wire |

|---|---|---|

| Corrosion Resistance | Excellent – zinc coating provides strong protection | Poor – prone to rust in humid conditions |

| Appearance | Bright, silver or shiny finish | Dark, matte black or grey surface |

| Durability | Long-lasting, especially outdoors | Shorter lifespan without protection |

| Cost | Higher due to added coating | Lower and more economical |

| Flexibility | Less flexible due to coating | Highly flexible and easy to bend |

| Use Case | Outdoor fencing, marine, construction | Binding, packaging, indoor tying |

Applications of Galvanized Wire

-

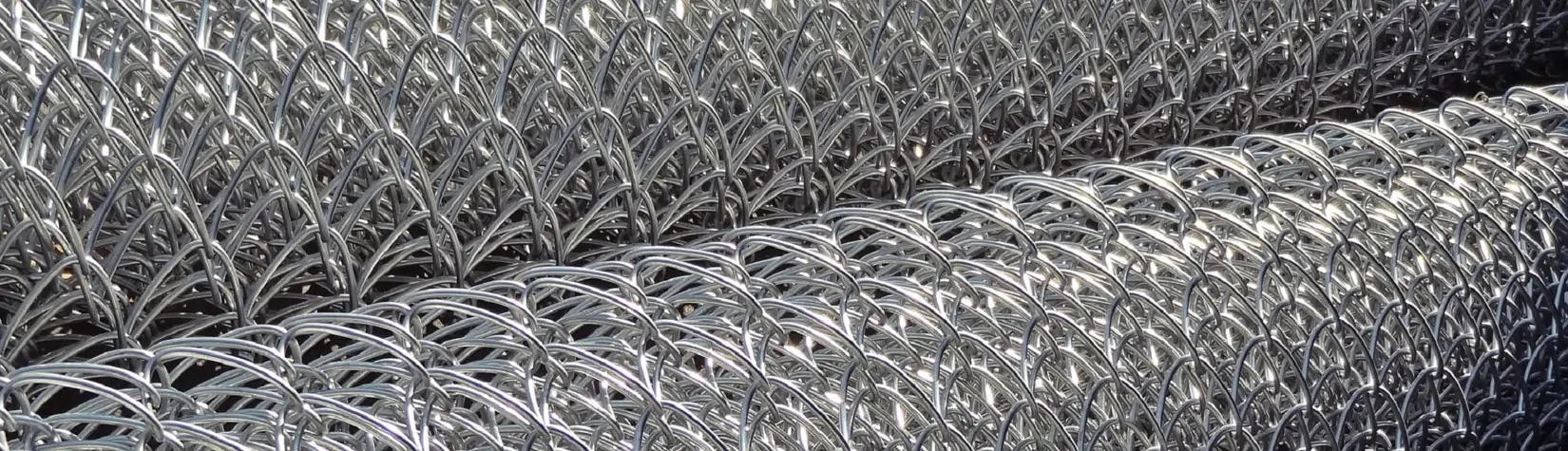

Fencing: Used in chain-link fences, barbed wire, and agricultural fencing to prevent rust and withstand weather elements.

-

Construction: Reinforces concrete structures, used in suspending ceilings, and holding scaffolding materials.

-

Automotive Industry: Used in making parts that require corrosion resistance.

-

Electric Cable Armor: Protects internal wires from physical damage and corrosion.

-

Crafts and Garden Work: Common in DIY projects, trellises, and plant supports for outdoor use.

Applications of Black Wire

-

Rebar Tying: Used by construction workers to bind rebar and reinforcement bars due to its flexibility.

-

Baling Wire: Common in agriculture and recycling industries to bundle materials like hay, paper, or cardboard.

-

Packaging: Secures heavy products or boxes in warehouses or during transport.

-

Manufacturing: Used in the production of nails, wire mesh, and barbed wire.

-

Crafting and Hobbies: Preferred by artists and sculptors for ease of shaping.

Choosing Between Galvanized and Black Wire

When deciding which wire to use, consider the following factors:

1. Environment

-

If your application is outdoors, exposed to rain, snow, or humidity, galvanized wire is the better choice.

-

For indoor or temporary projects, black wire offers flexibility and cost savings.

2. Durability Needs

-

Galvanized wire lasts longer and offers better strength for heavy-duty tasks.

-

Black wire is suitable for short-term use or applications where long lifespan isn’t required.

3. Budget Constraints

-

Galvanized wire is more expensive, but it pays off in longevity.

-

Black wire is budget-friendly and works well where corrosion isn’t a factor.

4. Ease of Handling

-

Black wire is softer and easier to twist or tie, which is ideal for workers handling large volumes daily.

-

Galvanized wire may require more effort or tools for manipulation due to the coating.

Environmental Impact

Both galvanized and black wires are made from steel, which is recyclable. However, the galvanizing process involves zinc, which must be handled responsibly to avoid soil or water contamination. Proper recycling of galvanized wire ensures minimal environmental impact. Black wire, being untreated, is often easier to recycle but has a shorter useful life in many settings.

Final Thoughts

Whether you’re a contractor, manufacturer, farmer, or hobbyist, understanding the difference between galvanized wire and black wire ensures the success and safety of your project. Galvanized wire is your go-to for durability and corrosion resistance, while black wire offers flexibility and affordability for indoor or temporary needs.

Both wire types are indispensable in their own right. Choosing the right one depends on your specific application, environment, and budget. With the right choice, you can enhance efficiency, reduce maintenance costs, and extend the life of your infrastructure or product.