EN 10219 Welded Steel Hollow Sections: Key Suppliers and Market Overview in Europe

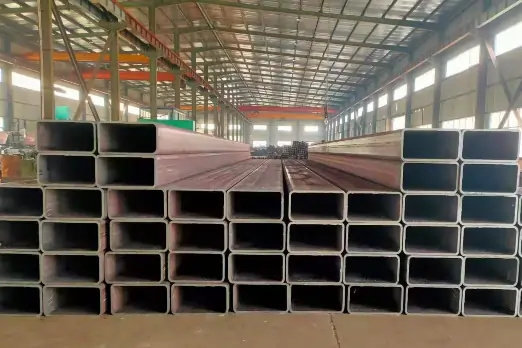

The European steel industry is known for its adherence to international standards, innovative manufacturing processes, and a well-structured supply chain. Among the essential steel products in the region are EN 10219 welded steel hollow sections, widely used in construction, engineering, and infrastructure projects. These sections, which include circular, square, and rectangular hollow profiles, are indispensable in modern structural design due to their strength, versatility, and cost-effectiveness.

This article explores the EN 10219 standard, the characteristics of welded hollow sections, and the leading suppliers and distributors in Europe who provide these products to diverse industries.

Understanding EN 10219 Hollow Sections

EN 10219 is the European standard covering cold-formed welded structural hollow sections of non-alloy and fine-grain structural steels. It specifies technical delivery conditions, chemical composition, mechanical properties, and dimensional tolerances.

Characteristics of EN 10219 Hollow Sections

-

Shapes: Available in circular, square, and rectangular profiles.

-

Grades: Includes structural steels such as S235JRH, S275J2H, and S355J2H, offering different levels of strength and toughness.

-

Manufacturing Method: Produced by cold forming and subsequently welded, resulting in precise dimensions and uniform wall thickness.

-

Versatility: Suitable for load-bearing and non-load-bearing applications.

-

Compliance: Conforms to strict European standards for mechanical performance and safety.

Advantages of EN 10219 Sections

-

Strength-to-Weight Ratio: Hollow sections offer structural integrity with reduced weight compared to solid sections.

-

Ease of Fabrication: Can be cut, welded, drilled, or bolted into complex structures.

-

Cost Efficiency: Economical in terms of both material use and installation.

-

Aesthetic Appeal: Clean lines and geometric shapes make them popular in architectural applications.

-

Durability: High resistance to buckling and torsion makes them ideal for demanding environments.

Applications of EN 10219 Hollow Sections

EN 10219 hollow sections are among the most widely used structural steel products in Europe, serving both civil and industrial sectors.

Construction and Infrastructure

They are used in high-rise buildings, stadiums, bridges, and airports where load-bearing capacity and design flexibility are critical.

Mechanical Engineering

Hollow sections are utilized in machinery frames, equipment supports, and transport systems requiring robust yet lightweight components.

Renewable Energy

Wind turbine towers, solar panel supports, and other green energy structures incorporate EN 10219 sections due to their reliability and strength.

Transportation

Railway bridges, trailers, and heavy-duty vehicles use these sections for their combination of strength and reduced weight.

Architectural Projects

Their geometric uniformity and sleek profiles make them suitable for visible structures like facades, roof trusses, and modern steel frameworks.

Key Suppliers of EN 10219 Hollow Sections in Europe

Europe is home to some of the world’s largest steel manufacturers and distribution networks, ensuring a stable supply of EN 10219 hollow sections across the region. Suppliers range from integrated steel producers to specialized stockholders and regional distributors.

Major European Steel Producers

Large steel groups operate across multiple European countries, producing welded hollow sections according to EN 10219 standards. These companies control the full value chain, from steelmaking to finished hollow sections, and supply both domestic and export markets. Their extensive product ranges cover all section sizes, wall thicknesses, and grades required for construction and industry.

Regional Stockholders and Service Centers

Across Europe, numerous service centers and stockholding companies specialize in hollow sections. These suppliers maintain large inventories of EN 10219-compliant tubes in circular, square, and rectangular shapes. They serve regional markets with quick delivery and often provide value-added services such as sawing, drilling, shot-blasting, and priming.

Specialized Tubing Distributors

Some companies focus exclusively on tubular products, including structural hollow sections, mechanical tubes, and line pipes. Their expertise ensures precise compliance with EN standards and provides engineering support to customers working on specialized projects.

Geographic Overview of Supply

Western Europe

Countries such as Germany, France, and the Benelux region have strong supplier networks. Many leading manufacturers and distributors are based here, supporting Europe’s largest construction markets.

Southern Europe

Italy and Spain host both producers and distributors that export hollow sections throughout Europe and North Africa. Their steel industries are well integrated with shipping networks, making them strategic suppliers.

Eastern Europe

Poland, Czech Republic, and Romania have growing steel production capacities, supplying both local demand and Western European projects. These regions often provide cost-competitive hollow sections while meeting EN 10219 requirements.

Northern Europe

The Nordic countries emphasize sustainability in steel production, with suppliers offering hollow sections manufactured using green energy and recycled steel.

Factors to Consider When Selecting a Supplier

Choosing the right supplier for EN 10219 hollow sections depends on project requirements, logistics, and technical specifications. Key considerations include:

-

Compliance and Certification: Ensure materials are supplied with EN 10219 certification and mill test reports.

-

Range of Dimensions: Access to a wide selection of profiles and wall thicknesses ensures flexibility for engineers and architects.

-

Delivery Speed: Local stockholding and efficient logistics are crucial for meeting tight project timelines.

-

Value-Added Services: Pre-processing such as cutting to length, surface treatments, and customization can reduce fabrication costs.

-

Sustainability Practices: Many European suppliers now emphasize eco-friendly steel production, aligning with EU green policies.

The Role of Sustainability in the European Steel Market

Sustainability is a central theme in Europe’s steel industry, and hollow section suppliers are no exception. Many producers are investing in decarbonized steelmaking, hydrogen-based processes, and circular economy models. By sourcing EN 10219 hollow sections from suppliers with strong environmental commitments, construction and engineering companies can reduce the carbon footprint of their projects.

Future Outlook for EN 10219 Hollow Sections in Europe

Demand for EN 10219 welded steel hollow sections is expected to remain strong in Europe, driven by several key factors:

-

Urbanization and Infrastructure Growth: Expansion of cities and modernization of transport networks will continue to boost demand.

-

Renewable Energy Projects: The transition to renewable energy requires large volumes of structural steel, including hollow sections.

-

Sustainable Construction Practices: Lightweight, efficient, and recyclable steel sections align with Europe’s green building standards.

-

Cross-Border Trade: The integrated European market ensures that hollow sections move freely across countries, allowing suppliers to serve international projects efficiently.

Conclusion

EN 10219 welded steel hollow sections form the backbone of Europe’s construction, engineering, and industrial sectors. Their combination of strength, precision, and versatility makes them indispensable in applications ranging from skyscrapers and bridges to renewable energy installations.

Europe’s supplier base for EN 10219 hollow sections is both deep and diverse, including global steel producers, regional distributors, and specialized service centers. Together, they ensure that manufacturers, contractors, and architects across the continent have access to reliable, compliant, and sustainable steel products.