Channel steel—often called C-channel, U-channel, or simply “channels”—is a fundamental structural section used across construction, fabrication, machinery, and infrastructure projects. In Pakistan, channel steel forms a core part of the local steel products mix, supplying builders, fabricators, and industrial manufacturers with versatile, economical structural members. This article outlines the manufacturing landscape for channel steel in Pakistan, typical product ranges and specifications, production methods, quality considerations, market applications, supply-chain dynamics, and outlook for the sector.

What is Channel Steel and Why It Matters

Channel steel is a hot-rolled or cold-formed section with a distinctive U-shaped cross-section. It combines a high strength-to-weight ratio with ease of connection and fabrication, making it ideal for frameworks, purlins, bracing systems, machine beds, railings, and architectural components. Compared with I-beams or H-sections, channels are easier to handle and often more economical for medium-duty structural uses. For Pakistan’s fast-growing construction and manufacturing sectors, channel steel provides a pragmatic balance between cost, availability, and performance.

Manufacturing Methods Used in Pakistan

Manufacturers in Pakistan produce channel steel using two primary methods: hot rolling and cold forming. Each method has advantages and typical use cases.

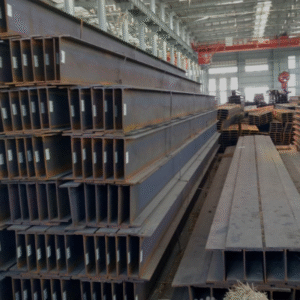

Hot-Rolled Channels

Hot-rolled channel sections are made by reheating steel billets or blooms and passing them through rolling mills to form the U-shaped profile. This method is common for heavier channels with thicker webs and flanges and is preferred where toughness and dimensional stability at larger sizes are required. Hot-rolled channels are often supplied in longer lengths and are suited for heavy structural and infrastructure applications.

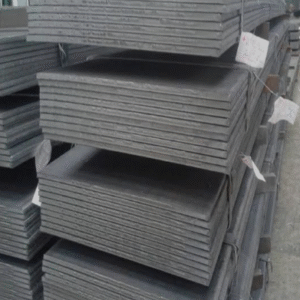

Cold-Formed (Cold-Rolled) Channels

Cold-formed channels are manufactured from flat steel coils that are slit and bent through roll-forming lines at room temperature. Cold forming allows tight dimensional control and produces thin-walled channels with consistent geometry. These channels are widely used in building purlins, light framing, shelving systems, and automotive or appliance components, where lighter gauge and precision are important.

Typical Grades, Sizes, and Tolerances

Channel steel in Pakistan is produced from a range of carbon and low-alloy steels to suit different mechanical requirements. The most commonly used grades correspond to non-alloy structural steels that provide a balance of ductility, weldability, and tensile strength.

Typical Material Grades

-

General structural carbon steel grades (mild steel) for everyday construction use.

-

Higher strength or low-alloy variants for heavier-duty or engineered applications where increased yield and tensile strength are required.

-

Galvanized options or surface-treated channels for corrosion resistance in exterior or humid environments.

Common Size Ranges

-

Depths from around 50 mm up to 300 mm or more for hot-rolled channels.

-

Flange widths and web thicknesses vary by producer; small cold-formed channels can be as narrow as 20–30 mm while heavy hot-rolled channels reach large cross sections.

-

Lengths typically supplied in standard mill lengths (6–12 meters) or cut to customer requirement.

Manufacturers generally offer custom slitting, punching, or hole patterns upon request.

Tolerances and Surface Finish

Producers adhere to practical tolerances for section dimensions and straightness. Surface finishes range from plain mill finish to galvanized coatings or primer paint. For architectural uses, polished or pre-painted channels may be available through value-added finishing facilities.

Manufacturing Capabilities and Value-Added Services

Pakistani channel steel manufacturers often provide a range of value-added services that help buyers receive near-ready components. These services typically include:

-

Coil slitting and tailored roll-forming for cold-formed channels.

-

Cutting to length, end-preparation, and bevelling for hot-rolled channels.

-

Punching, drilling, and slotting for ease of assembly on site.

-

Galvanizing, painting, or other protective coatings.

-

Bundling, packaging, and logistics arrangements for domestic distribution and export.

Many large service centers and distributors in Pakistan combine inventory with these processing capabilities, enabling quick turnaround for contractors and OEMs.

Market Applications in Pakistan

Channel steel finds broad use across Pakistan’s economy:

Construction and Infrastructure

Channels are used for roof purlins and girts, steel frames for industrial sheds, staircases, handrails, and support structures. Their economy and adaptability make them a go-to component for both formal construction and smaller civil works.

Manufacturing and Fabrication

Fabrication shops rely on channels for machine bases, conveyor supports, racking systems, and light structural frames. Cold-formed narrow channels are common in furniture, shelving, and storage solutions.

Energy and Utilities

Channels serve as supports for cable trays, mounting rails for solar panel frames, and as structural components in water and wastewater treatment plants.

Transportation and Heavy Industry

Larger hot-rolled channels are used in vehicle trailers, crane rails, and supportive members in heavy equipment. Channels are often paired with plates or angles to create composite sections.

Quality Control, Standards, and Testing

Quality control is central to reputable manufacturers. Practices and checkpoints include:

-

Incoming raw material inspection—checking chemical composition and mill certificates.

-

Dimensional checks and straightness tests on finished sections.

-

Mechanical testing (tensile, yield, elongation) on representative samples for structural grades.

-

Coating thickness measurement for galvanized or coated products.

-

Documentation and traceability with mill test reports and certificates of conformity.

Buyers should request material certificates and inspection reports, particularly for structural or safety-critical applications. Where projects demand it, third-party inspection and compliance with international or national standards can be arranged.

Supply Chain and Distribution Dynamics

Channel steel supply in Pakistan combines domestic mill output and imports. Larger integrated mills produce hot-rolled sections and wide coils, while smaller specialized manufacturers and service centers handle cold-formed strip and value-added processing. Distribution channels include:

-

National distributors and service centers that hold stock for rapid delivery.

-

Regional dealers serving construction clusters in major cities.

-

Direct mill sales for large industrial or export orders.

Logistics and inland transport are key cost drivers. Manufacturers that maintain strategically located warehouses in industrial hubs can reduce lead times and freight costs for buyers.

Pricing Factors and Commercial Considerations

The price of channel steel in Pakistan depends on several variables: steel raw material costs (hot rolled coil prices), section size and gauge, coatings, processing required, order quantity, and logistics. Bulk orders secure better per-unit pricing, while custom slitting, galvanizing, or pre-fabrication increase unit cost but reduce on-site labor and time.

When sourcing, buyers should consider total landed cost—material price plus cutting, coating, transport, and potential rework—rather than focusing solely on per-ton material cost.

Challenges and Opportunities

The channel steel sector in Pakistan faces familiar industry challenges: volatility of raw material prices, energy and power supply constraints, and the need for continued investment in modern rolling and finishing equipment. On the opportunity side, rising infrastructure spending, growth in renewable energy installations, and expanding manufacturing create steady demand for both standard and specialized channel profiles.

Investments in quality control, certifications, and environmentally friendly processing (such as efficient galvanizing and waste recycling) can help manufacturers differentiate their offerings and tap export markets across the region.

Choosing a Manufacturer or Supplier

Buyers should evaluate manufacturers on production capacity, quality assurance practices, lead times, ability to deliver value-added processing (slitting, punching, galvanizing), and after-sales support. Requesting mill test reports, sample sections, and visiting production sites where feasible helps verify supplier claims. For critical structural projects, prioritize suppliers that can provide documented conformity to specifications and support on welding, bolting, and installation guidance.

Conclusion

Channel steel remains an indispensable structural product across Pakistan’s construction and industrial landscape. Manufacturers in the country offer a mix of hot-rolled and cold-formed channels across a range of sizes and grades, supported by value-added services that meet the needs of contractors and fabricators. As Pakistan continues to expand its infrastructure and manufacturing base, the market for channel steel presents both stable demand and avenues for innovation—especially for suppliers who emphasize quality, service, and efficient logistics.