ASTM A623 Tinplate Steel and ASTM A500 Welded Structural Pipes

-

ASTM A500 structural tubing price A Complete 1200-Word Guide for Buyers, Fabricators & Construction Professionals

-

EN10025 S420M price A Complete 1000-Word Guide for Buyers, Engineers & Construction Professionals

-

ASTM A992 beam cost per kg A Complete 1000-Word Guide for Builders, Engineers & Procurement Teams

ASTM A623 Tinplate Steel and ASTM A500 Welded Structural Pipes: Key Suppliers and Market Insights in the United States

The steel industry in the United States is diverse and advanced, serving both domestic and international markets with specialized products that meet strict standards. Two important categories in this field are ASTM A623 tinplate steel and ASTM A500 welded structural pipes. Each serves a different set of industries but shares the common theme of reliability, compliance, and wide applicability.

This article explores the significance of these materials, their applications, and the key suppliers and distributors in the U.S. market who ensure consistent supply to manufacturers, fabricators, and end-users.

Understanding ASTM A623 Tinplate Steel

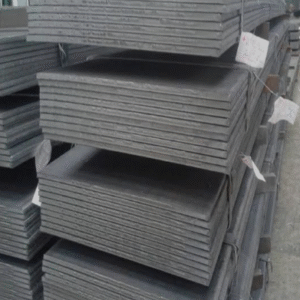

ASTM A623 is the standard specification that governs tinplate steel, often referred to as “tin mill products.” Tinplate is essentially a thin sheet of low-carbon steel coated with a thin layer of tin, applied either by hot-dipping or electrolytic processes. The tin layer provides corrosion resistance while maintaining the strength and formability of the steel base.

Characteristics of ASTM A623 Tinplate

-

Corrosion Resistance: The tin coating prevents rust and degradation, making it highly suitable for packaging.

-

Formability: Tinplate can be easily shaped into cans, containers, or other forms without losing structural integrity.

-

Food Safety: Safe for direct contact with food, resistant to moisture and air.

-

Surface Finish: Available in bright, matte, or stone finishes depending on end-use requirements.

-

Recyclability: Fully recyclable, supporting sustainability goals.

Applications of Tinplate Steel

-

Food and Beverage Packaging: Canned fruits, vegetables, soups, and drinks rely on tinplate containers for shelf life extension and flavor preservation.

-

Non-Food Packaging: Paints, chemicals, and aerosol products use tinplate cans to protect contents and prevent leaks.

-

Consumer Goods: Tinplate is used in toys, decorative items, and electronics.

-

Industrial Products: Specialty oils and lubricants often use tinplate containers due to their protective properties.

Key Tinplate Steel Suppliers in the United States

Several suppliers across the country specialize in tinplate steel, adhering to ASTM A623 standards. These companies not only provide raw materials but also offer value-added services such as slitting, sheeting, and surface treatment.

National and Regional Steel Producers

Large U.S. steel producers manufacture electrolytic tinplate and tin-free steel, supplying both domestic packaging companies and export markets. Their operations include integrated steel mills and service centers strategically located to minimize logistics costs.

Service Centers and Distributors

Independent service centers play a crucial role by stocking tinplate coils and sheets in various thicknesses and finishes. They cater to small and medium-sized manufacturers who may not purchase directly from large mills. These distributors often provide custom cutting, smaller order volumes, and fast turnaround times.

Specialty Tin Mill Suppliers

Some U.S. suppliers focus solely on tin mill products, offering expertise in meeting packaging industry requirements. These companies understand the specific needs of food and beverage manufacturers, providing material that complies with safety, sustainability, and performance standards.

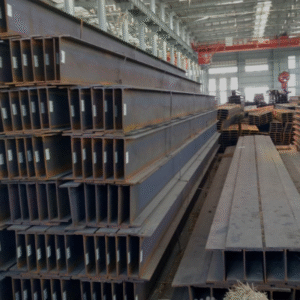

Understanding ASTM A500 Welded Structural Pipes

ASTM A500 is the standard specification for cold-formed welded and seamless carbon steel structural tubing. Unlike tinplate, which serves packaging and consumer markets, A500 structural tubing is essential in construction and engineering.

Characteristics of ASTM A500 Pipes

-

Shapes: Available in round, square, and rectangular cross-sections.

-

Grades: Multiple grades (A, B, C, D) with varying tensile strengths and yield strengths.

-

Welded Structure: Electric resistance welded (ERW) tubing ensures consistent wall thickness and dimensional accuracy.

-

Versatility: Can be used in load-bearing, architectural, and mechanical applications.

-

Cost-Effectiveness: Provides structural performance at an economical cost compared to hot-finished seamless tubes.

Applications of ASTM A500 Pipes

-

Construction: Widely used in building frames, columns, bridges, and infrastructure.

-

Fabrication: Common in machinery frames, supports, and industrial equipment.

-

Architectural Projects: Decorative structural tubing in commercial and residential buildings.

-

Transportation: Used in trailers, vehicle frames, and other heavy-duty equipment.

Key Distributors of ASTM A500 Structural Pipes in the U.S.

The U.S. has a strong distribution network for welded structural tubing, ensuring availability for projects of all sizes.

Large Steel Service Centers

National distributors maintain a vast inventory of ASTM A500 pipes in various grades, sizes, and wall thicknesses. They support major construction projects, ship large quantities, and often provide custom cutting and fabrication services.

Regional Suppliers

Regional suppliers cater to construction companies and contractors with faster delivery times and local warehousing. They often offer flexible order sizes and just-in-time delivery, which is essential for fast-paced projects.

Specialized Pipe Distributors

Some companies specialize specifically in hollow structural sections (HSS). These distributors focus on ASTM A500 pipes and provide technical support to engineers and fabricators who need assistance with grade selection and load-bearing requirements.

Comparing Supply Dynamics

Although ASTM A623 tinplate and ASTM A500 welded pipes serve different industries, their supply chains share some similarities.

-

Reliability of Supply: Both require consistent quality and availability. Packaging companies cannot afford downtime due to material shortages, and construction projects depend on timely deliveries.

-

Customization: Whether it is the finish on tinplate or the dimensions of a structural tube, customization is a key value-added service offered by suppliers.

-

Logistics: Both products are heavy and costly to transport, so regional suppliers and strategically located warehouses are crucial.

-

Quality Assurance: Suppliers must meet ASTM specifications to ensure compliance with food safety standards (for tinplate) or structural codes (for A500 pipes).

Choosing the Right Supplier

For manufacturers, contractors, or packaging companies, selecting the right supplier involves evaluating several factors:

-

Compliance with ASTM Standards: Ensure suppliers provide certification and mill test reports for A623 or A500 materials.

-

Inventory and Availability: Look for suppliers who stock a wide range of sizes, grades, and finishes to reduce lead times.

-

Value-Added Services: Services such as coil slitting, cut-to-length, shearing, or pipe cutting can save time and cost.

-

Reputation and Experience: Established suppliers with industry experience provide reliability and technical expertise.

-

Sustainability Practices: Especially for tinplate, working with suppliers who emphasize recycling and eco-friendly processes supports environmental goals.

The Role of U.S. Suppliers in Global Markets

The United States not only supplies its domestic industries but also exports both tinplate and structural pipes. Food packaging companies worldwide import tinplate from U.S. mills, while international construction projects source A500 pipes from American distributors due to their quality and adherence to standards. This dual role makes the U.S. a significant player in the global steel market.

Conclusion

ASTM A623 tinplate steel and ASTM A500 welded structural pipes are essential products in two very different industries: packaging and construction. Both rely on high-quality materials, consistent supply, and adherence to strict standards. In the United States, a strong network of producers, distributors, and service centers ensures that these materials are available for everything from canned food production to high-rise building projects.

For businesses seeking reliable partners, U.S. suppliers of tinplate steel and A500 structural pipes provide not only the raw materials but also value-added services, technical expertise, and logistical support. By choosing the right supplier, manufacturers and contractors can ensure performance, safety, and long-term success in their industries.