Steel in Mechanical and Electrical Engineering: A Midwest Perspective

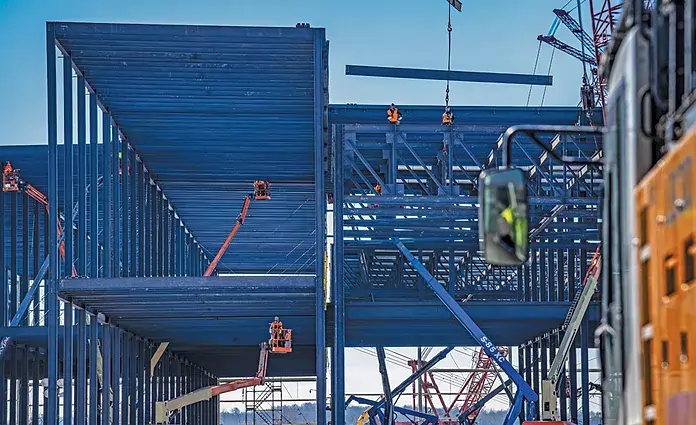

Steel is the backbone of industrial America. In the fields of mechanical and electrical engineering, steel serves as a crucial material—supporting infrastructure, enabling innovation, and ensuring reliability across a wide array of applications. Nowhere is this truer than in the U.S. Midwest, a region that has long stood at the crossroads of American manufacturing, engineering, and raw material supply.

With a strong heritage in steel production and a concentration of engineering-focused industries, the Midwest remains a central hub for the use and transformation of steel in both mechanical and electrical domains. This article explores the vital role steel plays in engineering applications and the unique advantages of sourcing and working with steel in the Midwest.

Steel’s Role in Mechanical Engineering

Mechanical engineering, at its core, deals with machines, structures, and the forces acting upon them. Steel is indispensable in this field due to its strength, durability, and adaptability.

Structural Applications

Steel is widely used in machine frames, support columns, shafts, fasteners, springs, and drive components. Grades such as A36 (for general structural use), 4140 (for high-strength shafts), and 1045 (for balanced strength and machinability) are common.

Steel’s strength-to-weight ratio and fatigue resistance make it ideal for mechanical systems where both static and dynamic loads are present. Components like gears, couplings, crankshafts, and axles often rely on medium-to-high carbon steels for optimal performance.

Heat Treatment and Machinability

One of steel’s key advantages in mechanical engineering is its tunability. Through heat treatment—annealing, quenching, tempering—engineers can drastically modify its hardness, strength, and ductility to suit specific needs.

Alloyed steels, such as those containing chromium, molybdenum, or vanadium, offer even greater flexibility. For instance, 4340 steel, widely used in high-load aircraft components, can reach tensile strengths exceeding 250 ksi when properly treated.

In the Midwest, regional machine shops and steel processors regularly supply pre-heat-treated steel, saving manufacturers time and cost.

Steel in Electrical Engineering

Although not the first material associated with electrical engineering (copper and aluminum usually top that list), steel plays a surprisingly vital role in the field.

Magnetic Steels

Electrical engineering applications often involve magnetic fields. Silicon steel, a low-carbon alloy infused with 1-4% silicon, is the material of choice for transformers, electric motors, and generators. The Midwest houses several facilities that produce grain-oriented and non-oriented electrical steel, essential for efficient electromagnetic performance.

Grain-oriented steel is designed for directional magnetic flow, improving transformer efficiency. Non-oriented variants are used in rotating machines such as electric motors, where magnetic flux is more uniform.

Enclosures and Mounting Systems

Steel is widely used in electrical cabinets, junction boxes, raceways, cable trays, and transformer enclosures due to its strength, formability, and ability to be coated for corrosion protection. In industrial and commercial electrical installations, steel conduit remains a trusted standard due to its grounding capabilities and physical protection.

Engineers typically specify galvanized or stainless steel depending on the environmental exposure and required lifespan.

Structural Support for Electrical Systems

Beyond conducting electricity, electrical systems need a mechanical backbone. Steel provides the frames and supports that mount busbars, panelboards, lighting fixtures, and switchgear. Hot-rolled angles and channels, cold-formed studs, and perforated steel sheets are staples in industrial electrical engineering design.

Why the Midwest?

Proximity to Mills and Distributors

The Midwest is uniquely positioned with direct access to some of the largest steel producers in the country, including mills in Indiana, Ohio, Michigan, and Illinois. Nucor, Cleveland-Cliffs, Steel Dynamics, and U.S. Steel operate major facilities in this region, supplying everything from hot rolled coil to specialized electrical steel.

Distributors and service centers such as Ryerson, Phoenix Steel Service, and Central Steel & Wire ensure regional access to ready-to-ship inventory. This reduces lead time, cost, and transportation complexity for engineering firms.

Engineering Talent and Industry Clusters

The Midwest is home to some of the top engineering schools in the country—University of Michigan, Purdue, UIUC, and others—feeding the region’s robust manufacturing and R&D ecosystem. Industries such as automotive, aerospace, HVAC, robotics, and energy storage all depend on steel and strong mechanical-electrical collaboration.

Companies operating in this region benefit from both skilled labor and an industrial culture steeped in steel knowledge.

Common Steel Types Used in Midwest Engineering Projects

| Grade | Type | Typical Use |

|---|---|---|

| A36 | Mild structural | Frames, brackets, supports |

| 1018 | Cold finished | Shafts, pins, spacers |

| 1045 | Medium carbon | Gears, axles, couplings |

| 4140/4340 | Alloy steel | High-stress parts, aerospace, and heavy machinery |

| 304/316 | Stainless steel | Electrical enclosures, corrosive environments |

| Silicon Steel (CRGO) | Electrical grade | Transformers, motors, generators |

| G90 Galvanized | Zinc-coated mild | Electrical boxes, conduit, mounting rails |

Sustainability and Recyclability

Steel is 100% recyclable without loss of quality. For engineering firms focused on sustainable design and LEED certification, sourcing recycled steel or working with mills that operate electric arc furnaces (EAFs) can align with environmental goals.

Midwest steel producers are increasingly integrating EAF processes, which rely on scrap metal rather than raw ore, reducing CO₂ emissions significantly.

Procurement and Logistics

For buyers procuring steel for engineering use, the Midwest offers a competitive edge in both price and availability. Service centers routinely offer:

-

Cut-to-length, slit coil, and bar processing

-

JIT delivery

-

Custom sourcing of specialty grades

-

Technical consultation for mechanical and electrical applications

Many firms benefit from developing long-term relationships with regional suppliers, ensuring consistent pricing, traceability, and material certifications such as ASTM, SAE, or MIL-SPEC compliance.

Case Studies in Application

Mechanical: Midwest Machine Tool Manufacturer

A Michigan-based precision machinery company sources 4140 steel bar stock from a Toledo distributor. After heat treatment to 38 HRC, the bars are machined into camshafts for automated stamping systems. Local sourcing allows 24-hour delivery, which has reduced inventory costs by 18% year-over-year.

Electrical: Transformer Manufacturer in Illinois

An Illinois-based manufacturer of medium-voltage transformers uses CRGO (cold-rolled grain-oriented) silicon steel laminated core material sourced from a mill in Indiana. Engineering staff perform in-house core stacking, relying on precise slitting to ±0.005” tolerance. Regional sourcing ensures material uniformity and electromagnetic efficiency.

Conclusion

Steel is not just a material of strength—it is a medium of precision, conductivity, adaptability, and design innovation. In the world of mechanical and electrical engineering, its value lies in its reliability and versatility.

The Midwest remains a powerhouse of steel-based engineering, offering advantages in logistics, talent, processing, and supply chain integration. Whether you’re designing high-speed shafts, building control cabinets, or sourcing magnetic core material for transformers, steel is foundational—and in the Midwest, it’s close to home.

For engineers and manufacturers alike, understanding steel’s properties and the regional advantages of Midwest sourcing is key to building better, smarter, and more sustainable products.