Steel Plate Coils: An Essential Component in Modern Industries

Steel Plate Coils: An Essential Component in Modern Industries . Steel plate coils are indispensable materials in various industries, including construction, automotive, shipbuilding, and manufacturing. Their versatility, strength, and adaptability make them a preferred choice for multiple applications. As demand for durable and cost-effective materials grows, steel plate coils continue to play a vital role in infrastructure development and technological advancements.

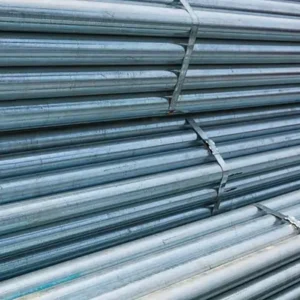

What Are Steel Plate Coils?

Steel plate coils are large sheets of steel that are rolled into coils for convenient transportation and processing. They are available in different thicknesses, widths, and grades, catering to diverse industrial needs. These coils are produced through hot rolling or cold rolling processes, each offering unique benefits suited to specific applications.

Types of Steel Plate Coils

Steel plate coils are categorized based on their manufacturing process, composition, and intended application. The two primary types include:

1. Hot Rolled Steel Plate Coils

Hot rolled steel plate coils are manufactured by heating steel slabs to high temperatures and then rolling them into thin sheets. The process enhances the steel’s ductility, making it suitable for applications requiring malleability and high-temperature resistance. Key characteristics include:

- Lower cost due to simplified production

- Higher strength for structural applications

- Good weldability for construction and fabrication

- Rougher surface finish due to the hot rolling process

2. Cold Rolled Steel Plate Coils

Cold rolled steel plate coils are processed at room temperature, resulting in a smoother surface and enhanced mechanical properties. These coils are widely used in industries where precision and aesthetic appeal are crucial. Key features include:

- Higher dimensional accuracy

- Improved surface finish

- Increased strength and hardness

- Better corrosion resistance

Applications of Steel Plate Coils

Steel plate coils serve as fundamental materials in numerous industries. Their durability and adaptability make them suitable for a wide range of applications, such as:

1. Construction Industry

Steel plate coils are extensively used in building structures, bridges, and infrastructure projects. Their high strength-to-weight ratio makes them ideal for:

- Beams and columns

- Roofing and siding panels

- Reinforced concrete structures

2. Automotive Industry

In the automotive sector, steel plate coils are used in manufacturing vehicle frames, body panels, and other critical components. Their impact resistance and formability enhance vehicle safety and durability.

3. Shipbuilding Industry

Marine applications require materials with excellent corrosion resistance and strength. Steel plate coils are used in hulls, decks, and structural reinforcements for ships and offshore platforms.

4. Manufacturing and Fabrication

Steel plate coils are widely used in producing machinery, pipelines, storage tanks, and other industrial components. Their ability to withstand extreme conditions makes them an essential material in fabrication.

Benefits of Using Steel Plate Coils

The widespread use of steel plate coils can be attributed to several advantages:

1. High Strength and Durability

Steel plate coils offer exceptional strength, making them suitable for demanding applications that require structural integrity and load-bearing capabilities.

2. Versatility

Available in different grades and finishes, steel plate coils cater to various industries, from heavy engineering to consumer goods manufacturing.

3. Cost-Effectiveness

Compared to other materials, steel plate coils offer a cost-effective solution due to their durability and recyclability, reducing material wastage.

4. Corrosion Resistance

Advanced coatings and treatments improve the corrosion resistance of steel plate coils, extending their lifespan in harsh environments.

Steel Plate Coil Manufacturing Process

The production of steel plate coils involves several key steps:

- Raw Material Selection: High-quality steel slabs are chosen based on the desired properties.

- Heating and Rolling: Steel slabs are heated and rolled into thin sheets using hot rolling or cold rolling techniques.

- Coiling: The sheets are coiled for easy storage and transportation.

- Surface Treatment: Coatings such as galvanization or painting are applied to enhance durability.

- Quality Inspection: The final product undergoes rigorous testing to ensure compliance with industry standards.

Choosing the Right Steel Plate Coil

Selecting the appropriate steel plate coil depends on factors such as:

- Application requirements: Strength, flexibility, and corrosion resistance

- Grade and composition: Carbon steel, stainless steel, or alloy steel

- Thickness and dimensions: Based on structural and design needs

- Coating and finishing: To enhance longevity and performance

Future Trends in Steel Plate Coil Industry

The steel industry continues to evolve with advancements in manufacturing technologies and sustainability initiatives. Key trends shaping the future include:

- Eco-Friendly Production: The adoption of energy-efficient processes and recycling methods to reduce environmental impact.

- Advanced Coatings: Development of innovative coatings to enhance corrosion resistance and longevity.

- Customization and Smart Manufacturing: Integration of AI and automation for precise manufacturing and tailored solutions.

- Lightweight and High-Strength Alloys: Research into new steel compositions to improve performance while reducing weight.

Conclusion

Steel plate coils remain a cornerstone of industrial development, offering unmatched strength, durability, and versatility. As industries continue to innovate, the demand for high-quality steel plate coils will rise, driving advancements in production techniques and material performance. Whether in construction, automotive, or shipbuilding, steel plate coils play a crucial role in shaping modern infrastructure and technology.