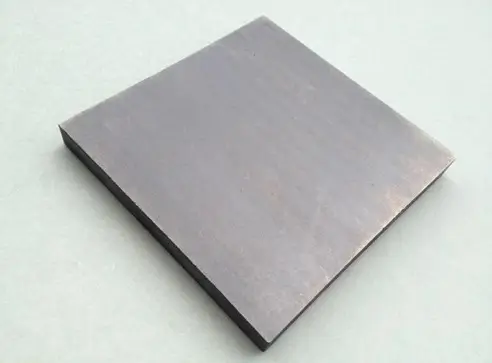

Powder High-speed Steel

Product Menu

- Steel Bar

- Powder High-speed Steel

- Aluminum Strip Coil/Sheet

- Stainless Steel Strip Coil/Sheet

- Hot-rolled Steel Strip Coil/Sheet

- Cold-rolled Steel Strip Coil/Sheet

- Galvanized Steel Strip Coil/Sheet

- Color-coated Steel Strip Coil/Sheet

- Seamless Steel Pipe

- Welded Steel Pipe

- H-shaped Steel

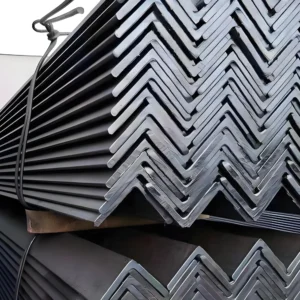

- Angle Steel/Channel Steel

| Product Origin: | China |

| MinimumOrder Quantity: | 1 KG |

| Packaging Details: | Standard export packaging or as per customer requirements. |

| Delivery Time: | 5 – 10days |

| Payment Method: | Letter of Credit, Telegraphic Transfer, Western Union Remittance |

| Supply Capacity: | 3,000 tons per month |

| Delivery Method: | FOB/CFR/CNF/CIF/EXW |

Product Description

Overview of Powder High-Speed Steel Products:

- Core Definition:

Powder high-speed steel is a type of high-speed steel produced using powder metallurgy technology. Molten steel is atomized into extremely fine powder by high-pressure gas or centrifugal force, then densified into steel ingots through hot isostatic pressing, and finally processed into materials by hot working.

- Core Technical Advantages: Compared with traditional cast and forged high-speed steel, its core advantages are:

No carbide segregation: It completely solves the problem of carbide inhomogeneity caused by traditional processes, with fine carbide particles and uniform distribution.

Higher alloy content: It can produce high-alloy grades (such as high vanadium and high cobalt) that cannot be smelted by traditional methods, achieving extremely high hardness, wear resistance and red hardness.

Isotropy: Mechanical properties and heat treatment deformation are consistent in all directions.

Excellent grindability: Even with high vanadium content, it still has good grindability due to fine carbides.

- Core Value Proposition:

Powder high-speed steel represents the pinnacle of high-speed steel technology. With its unparalleled wear resistance, excellent red hardness and consistent isotropic properties, it has become the preferred tool material for dealing with the most difficult-to-machine materials (such as titanium alloys, nickel-based superalloys, and high-hardness die steel). Although the cost is high, the improvement in processing efficiency and the extension of tool life brought by it make it irreplaceable in the field of high-end manufacturing.

Standard grades of powder high-speed steel:

| Product name | Grade | ASSAB | BOHLER | ERASTEEL | JIS | DIN | USA | Main chemical composition,wt% | Hardness range | ||||||

| C | W | Mo | Cr | V | Co | Nb | |||||||||

| Powder high-speed steel. | PM23 | PM23 | S790 | 2023 | SKH53 | 1.3345 | M3 | 1.3 | 6.3 | 5 | 4 | 3 | - | - | 64-66HRC |

| PMT15M | S390 | 2052 | - | - | - | 1.6 | 10.5 | 2 | 4.8 | 5 | 8 | - | 65-67HRC | ||

| PM60 | PM60 | - | 2060 | - | 1.3292 | - | 2.3 | 6.5 | 7 | 4.2 | 6.5 | 10.5 | 66-68HRC | ||

| PM290 | - | S290 | - | - | - | - | 2 | 14.2 | 2.5 | 3.8 | 5 | 11 | - | 67-70HRC | |

| Powder cold work tool steel. | PM504 | V4E | - | - | - | - | - | 1.4 | - | 3.5 | 4.7 | 3.7 | - | - | 60-64HRC |

| PM408 | PM53 | 2053 | - | 1.3352 | - | 2.5 | 4.1 | 3 | 4 | 8 | - | - | 60-65HRC | ||

| PM510 | - | - | 2011 | - | - | A11 | 2.4 | - | 1.3 | 5.2 | 9.7 | - | - | 60-64HRC | |

| Powder stainless tool steel. | PM204 | PMX818 | M390 | - | - | - | - | 1.9 | 0.6 | 1 | 20 | 4 | - | 59-62HRC | |

| PM205 | - | - | - | SAM39 | X235 | 2.3 | - | 1 | 20 | 4 | - | 2 | 60-63HRC | ||

| PM264 | - | - | - | SAM26 | - | 2.6 | - | 1.1 | 26 | 2.7 | - | 1.5 | 58-63HRC | ||

| PM163 | - | - | - | - | - | 545VN | 1.5 | - | 2 | 16 | 3 | - | 0.5 | 59-62HRC | |

| PM115 | - | - | - | - | - | MC | 1.2 | - | 2 | 10.7 | 4 | - | 2 | 59-62HRC | |

| Heat-resistant alloy steel. | PM2515 | - | MC90 | - | - | - | - | 15 | - | 25 | - | 65-68HRC | |||

| PM2905 | - | - | 2190 | - | - | - | 0.78 | 2.9 | 2.9 | 4.2 | 1.1 | 29 | 1.1 | 65-69HRC | |

| customization | |||||||||||||||

Properties and applications of powder high-speed steel:

| Product name | Grade | Characteristics | Applications | |

| Powder high-speed steel. | PM23 | Powder high-speed steel cutting tools have excellent wear resistance and toughness. | Suitable for high-performance cutting tools (taps), fine blanking dies, cold rolls, plastic injection molds, IC packaging molds, powder pressing, etc. | |

| PMT15M | Powder high-speed steel cutting tools have excellent wear resistance, toughness and good red hardness. | Suitable for cutting-formed multi-edge tools (broaches, gear cutters), single-edge tools (rolling/shearing blades), which require high wear resistance, as well as fine blanking dies, and are suitable for cold processing applications of IC molds. | ||

| PM60 | Powder high-speed steel cutting tools have excellent wear resistance, toughness and outstanding red hardness. | Suitable for cutting-formed multi-edge tools (gear cutters), single-edge tools (rolling/shearing blades), which require high wear resistance, as well as fine blanking dies, and are suitable for cold processing applications of IC molds. | ||

| PM290 | Powder high-speed steel cutting tools have high wear resistance. | Suitable for gear hobbing cutters, gear shapers, powder metallurgy dies, various high-speed cutting inserts, roll dies, and die-cutting knives. | ||

| Powder cold work tool steel. | PM504 | It has good wear resistance and meets the high requirements for resistance to adhesive wear and chipping in working conditions. | Suitable for cold working conditions such as blanking of thick plates, fine blanking, stamping forming, cold forging, cold extrusion, and powder pressing. | |

| PM408 | It has excellent wear resistance and high toughness. | Suitable for cold working applications such as blanking, fine blanking, stamping forming, cold forging, cold extrusion, and powder pressing. | ||

| PM510 | It has excellent wear resistance and relatively high toughness. | Suitable for wear-resistant components, punching, cold working dies, extrusion dies, and woodworking, paper cutting, and textile slitting applications. | ||

| Powder stainless tool steel. | PM204 | It has excellent corrosion resistance, wear resistance and outstanding polishability. | Suitable for outdoor knives, mirror molds, food processing components/knives, plastic screw injection molding, etc. | |

| PM205 | It has excellent corrosion resistance, wear resistance and outstanding polishability. | Suitable for outdoor knives, mirror molds, food processing components/knives, single and double screws of plastic machinery, injection molding molds, etc. | ||

| PM264 | It has relatively good corrosion resistance, wear resistance and relatively outstanding polishability | Suitable for single and double screws of plastic machinery, sleeve components, etc. | ||

| PM163 | It has relatively good corrosion resistance, wear resistance and relatively outstanding polishability | Suitable for outdoor knives, mirror molds, food processing components/knives, etc. | ||

| PM115 | It has relatively good corrosion resistance, wear resistance and relatively outstanding polishability. | Suitable for outdoor knives, kitchen knives, mirror molds, food processing components/knives, single and double screws of plastic machinery, injection molding molds, etc. | ||

| Heat-resistant alloy steel. | PM2515 | It has extremely excellent corrosion resistance, wear resistance, high toughness and relatively outstanding polishability. | Gear processing tools, gear shavers and gear shapers | |

| PM2905 | ||||

| customization | It has extremely high wear resistance and red hardness, good toughness and compressive strength, very high edge stability and easy grindability. | Exclusive grades, exclusive operation |

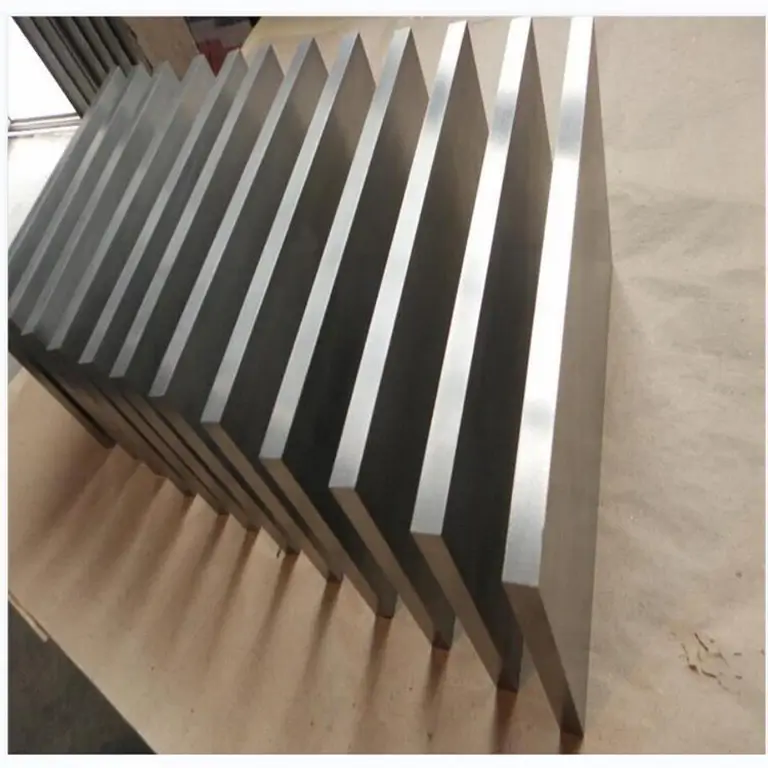

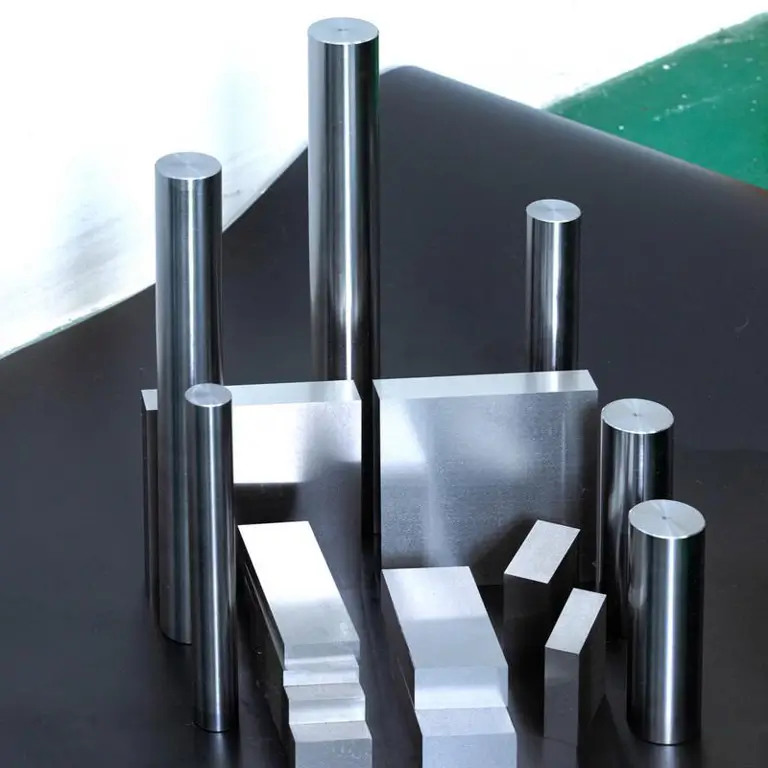

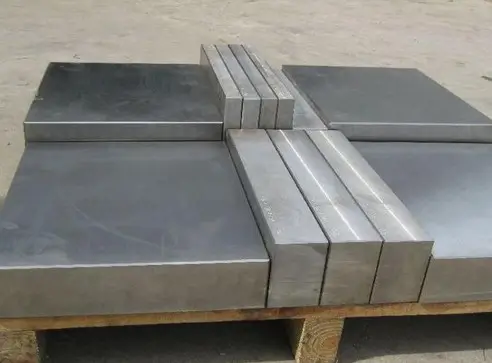

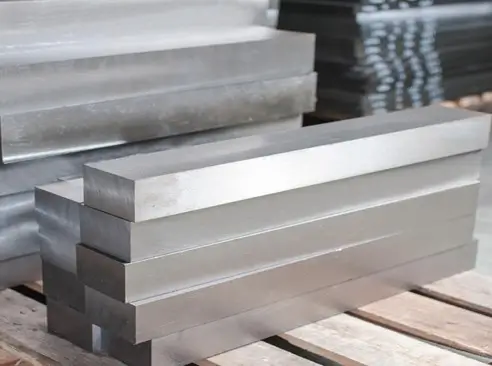

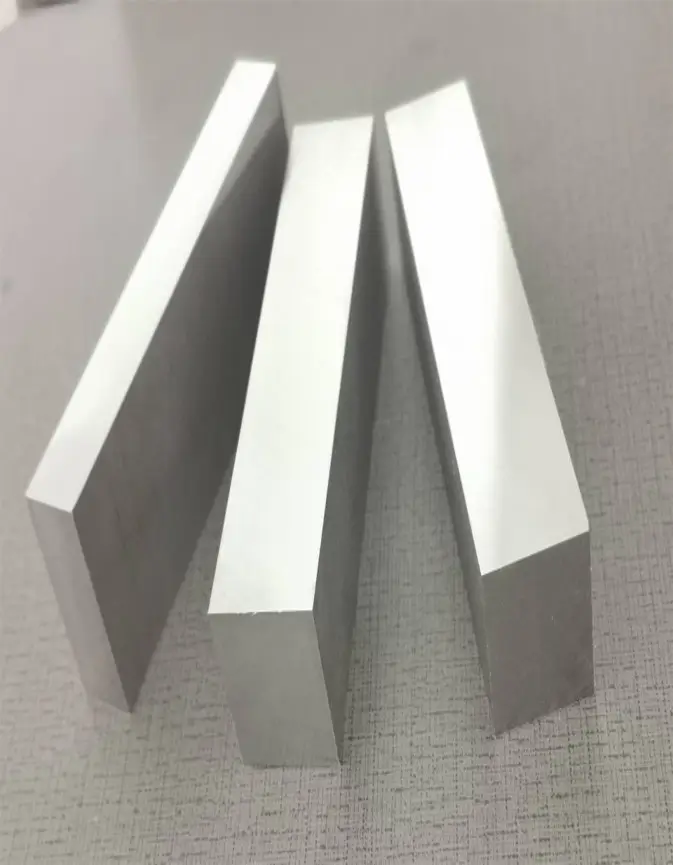

Form specifications of powder high-speed steel.:

| Product name | Grade | Specification/Form (Unit: mm) | |||

| Hot isostatic pressing. | Hot-rolled plate | Hot-forged square | Forged/rolled round | ||

| Powder high-speed steel. | PM23 | Starting from 1.5*850*L | 152*202*L 202*202*L 202*302*L 202*402*L |

Starting from 4.0 | |

| PMT15M | Hollow die-cutting knife. | Starting from 4.5*850*L | Starting from 4.0 | ||

| PM60 | Hollow die-cutting knife. | Starting from 4.5*850*L | Starting from 4.0 | ||

| PM290 | Hollow die-cutting knife. | - | |||

| Powder cold work tool steel. | PM504 | Starting from 3.5*850*L | 152*202*L 202*202*L 202*302*L 202*402*L |

Starting from 2.0 | |

| PM408 | Hollow die-cutting knife. | Starting from 4.5*850*L | Starting from 4.0 | ||

| PM510 | Hollow composite single and double screws | Starting from 4.5*850*L | Starting from 4.0 | ||

| Powder stainless tool steel. | PM204 | Hollow composite single and double screws | Starting from 1.5*850*L | 152*202*L 202*202*L 202*302*L 202*402*L |

- |

| PM205 | Hollow composite single and double screws | Starting from 3.5*850*L | |||

| PM264 | Composite single and double sleeves. | - | - | ||

| PM163 | Starting from 2.5*850*L | ||||

| PM115 | Composite single and double screws. | Starting from 1.5*850*L | Starting from 2.0 | ||

| Heat-resistant alloy steel. | PM2515 | Bimetallic composite rod/tube | - | Starting from 4.0 | |

| PM2905 | |||||

| customization | according to the customer's requirements | ||||

Midwest Steel Supply Services

OEM & ODM

Highly precise technical design team,the design and production of tailored solutions for you.

Contact

Similar Products

-

Sale!

Seamless Steel Pipe

$0.53 – $49.43Price range: $0.53 through $49.43 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

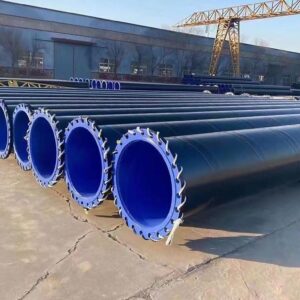

Welded Steel Pipe

$0.38 – $38.32Price range: $0.38 through $38.32 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

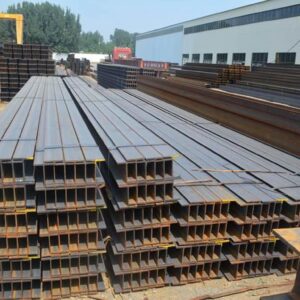

H-shaped Steel

$8.77 – $94.34Price range: $8.77 through $94.34 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

Angle Steel/Channel Steel

$2.85 – $36.94Price range: $2.85 through $36.94 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page