Color-coated Steel Strip Coil/Sheet

Product Menu

- Steel Bar

- Powder High-speed Steel

- Aluminum Strip Coil/Sheet

- Stainless Steel Strip Coil/Sheet

- Hot-rolled Steel Strip Coil/Sheet

- Cold-rolled Steel Strip Coil/Sheet

- Galvanized Steel Strip Coil/Sheet

- Color-coated Steel Strip Coil/Sheet

- Seamless Steel Pipe

- Welded Steel Pipe

- H-shaped Steel

- Angle Steel/Channel Steel

| Product Origin: | China |

| MinimumOrder Quantity: | 3 tons |

| Packaging Details: | Standard export packaging or as per customer requirements. |

| Delivery Time: | 5 – 8 days |

| Payment Method: | Letter of Credit/Telegraphic Transfer/Western Union Remittance/Open Account Trade |

| Supply Capacity: | 6,000 tons per month |

| Delivery Method: | FOB/CFR/CNF/CIF/EXW |

Product Description

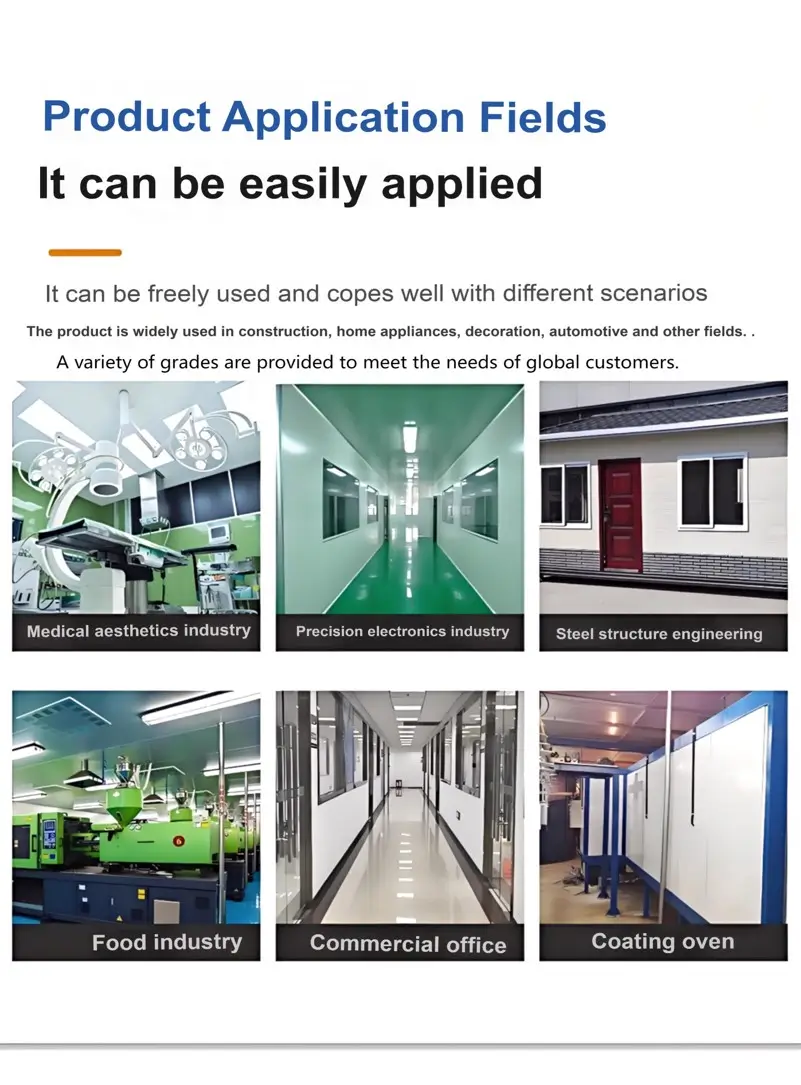

Overview of International Color Coated Steel Coils/Sheets Products:

- Core Definition:

Color-coated steel coils are composite materials made by using cold-rolled, hot-dip galvanized, or aluminum-zinc alloy coated steel sheets as the base plate, undergoing surface pretreatment (cleaning, conversion), continuously applying one or more layers of organic coatings (at least two layers on the front and usually one layer on the back), and then baking and curing. They combine the strength of the metal base plate with the aesthetics and weather resistance of polymer coatings.

- Main Features:

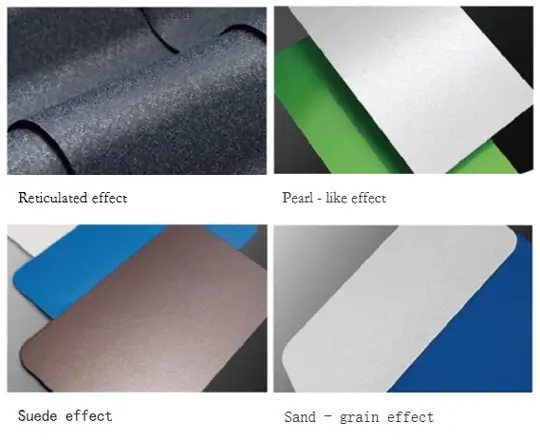

Decorativeness and diversity: Offering a variety of colors, gloss levels (high gloss, matte), and surface textures (flat, micro-velvet, embossed).

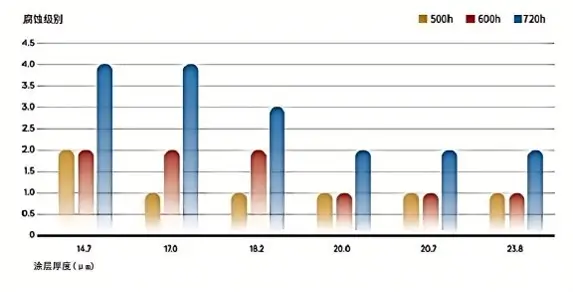

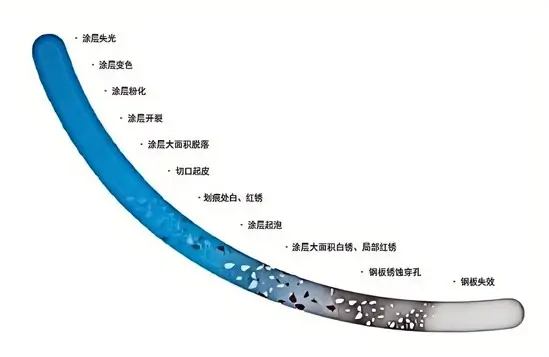

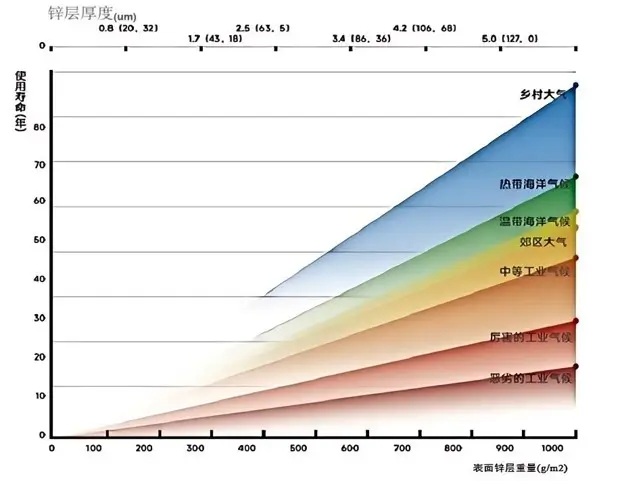

Excellent weather resistance and durability: High-quality coatings can resist ultraviolet rays, acid rain, and salt spray erosion, maintaining color and gloss for a long time.

Good processability: Allowing moderate bending, stamping, and forming.

Cost-effectiveness: Integrating protection and decoration, reducing the cost and time of secondary coating in manufacturing and construction sites.

- Core Structure and Process:

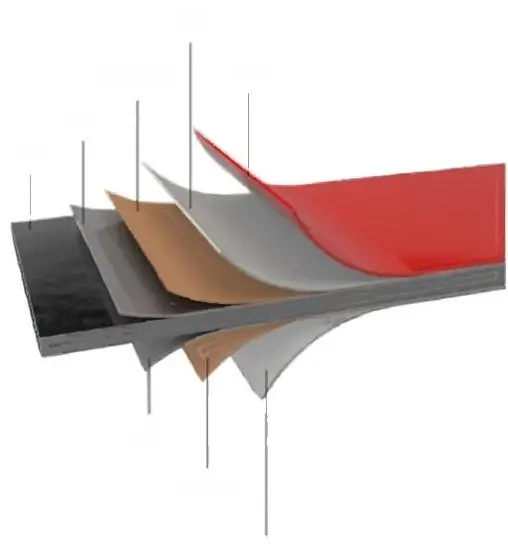

Base plate:

Hot-dip galvanized base plate: Providing basic anti-rust ability.

Aluminum-zinc coated base plate: Having better heat resistance and resistance to edge corrosion.

Cold-rolled base plate: Usually used indoors or in non-corrosive environments.

Coating system:

Primer coating: Mainly functioning in adhesion and corrosion resistance, commonly using epoxy or polyester types.

Top coating: Mainly providing color, weather resistance, and durability, commonly using polyester, silicon-modified polyester, high-durability polyester, and polyvinylidene fluoride.

- Core Value Proposition:

Through advanced composite material technology, color-coated steel coils achieve the perfect integration of protection, decoration, and functionality, providing long-lasting, beautiful, and sustainable lightweight material solutions for the global construction and manufacturing industries.

Standards and Grades of Color-Coated Steel Coils/Sheets

| Standard | Steel Grade | Coating | ||

| EN 10169 | Class A | Class B | Class R | Z/AZ |

| ASTM A755/755M/

AAMA 621 |

PET | SWP | Z//G | |

| PVDF | ||||

| JIS G3312 | SGH340 | SGH400 | SGH440 | Z/F |

| SGH490 | SGC400 | SGC440 | ||

| GB/T12754-2019 | PET | SWP | PVDF | Z/F/AZ/ZE/ZNE |

Midwest Steel Supply Services

OEM & ODM

Highly precise technical design team,the design and production of tailored solutions for you.

Contact

Similar Products

-

Sale!

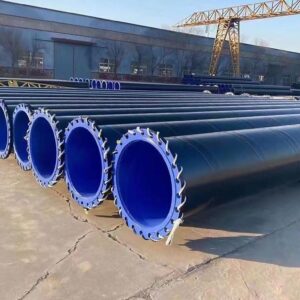

Seamless Steel Pipe

$0.53 – $49.43Price range: $0.53 through $49.43 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

Welded Steel Pipe

$0.38 – $38.32Price range: $0.38 through $38.32 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

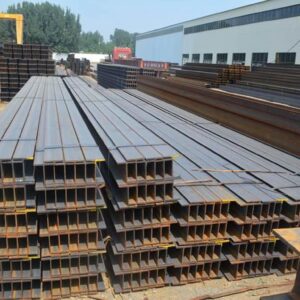

H-shaped Steel

$8.77 – $94.34Price range: $8.77 through $94.34 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page -

Sale!

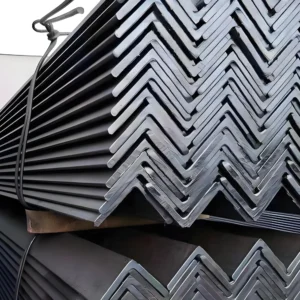

Angle Steel/Channel Steel

$2.85 – $36.94Price range: $2.85 through $36.94 /m Select optionsQuick View This product has multiple variants. The options may be chosen on the product page